Process Development Department

Process Departement Team

Process Departement TeamFeasibility studies and performance tests

With their database containing the details of some 14,000 studies - unrivalled anywhere in the world, the Process Development Department is there to help you choose the best solution for your specific application.

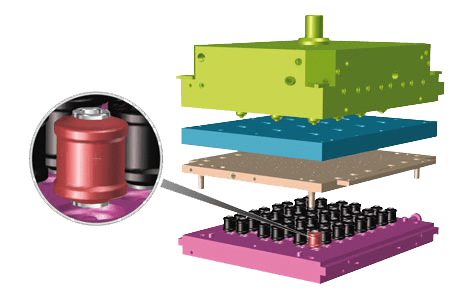

These solutions may be tried out under semi-industrial conditions in our test laboratory on all press models and over 40 molds.

Want to mold insulators, bladders, pharmaceutical stoppers, dampers, grommets, hoses, gaskets, etc?

Send us a part drawing or a sample specifying your requirements (productivity, compound used, press type, etc)

We will then produce a mold schematic drawing and a feasibility study in accordance with these elements.

The expert's opinion

" Whatever the missing link in your global project: cold runner block or full automated solution, mold, compound formula or peripheral equipment..., REP is in a position to help you and supply you with it so as to make your project successful."Matthieu Wolff, Process Development Engineer

Process Optimization Training Courses or Webinars

We invite you to come and benefit from the expert guidance of our engineers.

In a friendly atmosphere, you will attend a specialized training course ("Process and Mould Design" or "Adjustment of the Moulding Parameters").

Please consult our specific page dedicated to Training