Our Sustainability Promise

What is CSR about ?

The CSR (Corporate Social Responsibility) refers to all the practices put in place by companies so as to match the sustainable development principles, i.e.:

- be economically viable,

- have a positive impact on society,

- but also better respect the environment.

This concept has rapidly become a significant concern of companies during the past years. The current climate crisis requires indeed a rapid and global change. Companies must choose to implement energy and digital transition, and this must be in line with a sustainable progress.

The Beginnings of our CSR Strategy

It all started with the certificate of commitment to Corporate Social Responsibility delivered by the French Union of Metallurgy Industries (UIMM):

Hervé Revel receiving the certificate of commitment to Corporate Social Responsibility at a UIMM ceremony

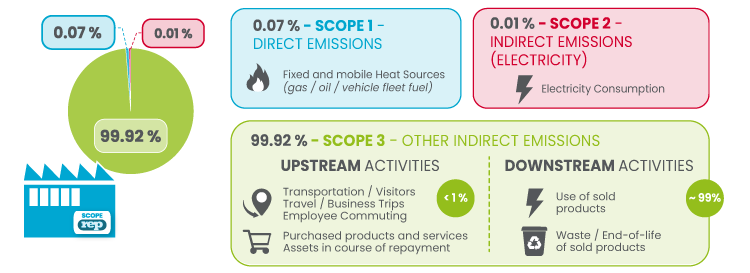

The second step consisted in estimating our carbon footprint

We assessed ourcarbon balance and started studying the solutions to be implemented for reducing our carbon footprint.

In the words of the Carbon Project Manager

As a manufacturer of rubber injection molding machines, our main CO2 emission source comes from the use of presses at the customers' sites, and precisely from rubber, which is subsumed under "scope 3: other indirect emissions".

Gas (55%) and electricity (17%), used to power and heat buildings, account for the highest energy consumption.

The insulation of our buildings becomes logically one of the first commitments we must take to reduce this consumption.

Lucas Thiérot, Quality Control Department

Our CSR Commitments

The REP road map encompasses multiple commitments

-

Reducing our CO2 emissions through an energy efficiency program

-

Developing ecodesign using a "redesign to cost" strategy

-

Providing our customers with sustainable and innovative solutions

-

Acting together with our suppliers via an Ethics Charter and REACH criteria

-

Advocating for transparency and honesty in the relations with our partners

The REP CSR commitments aim at integrating social, environmental and ethical issues into the company's global strategy.

In the words of the Quality Manager

Some criteria common to CSR and to the ISO9001 certification, such as:

structure our strategy and ensure a more qualitative management.

structure our strategy and ensure a more qualitative management.

- The recognition of the stakeholders' interest,

- The employees' involvement,

- A continuous improvement,

Catherine Nguyen, CEO Executive Assistant

REP is committed to reducing its CO2 emissions, whatever their origins are.

REP is bound by the "Décret tertiaire" (French tertiary sector decree) which coerces administrative buildings to reduce their energy consumption by 30% by 2030 in comparison with a chosen reference year (for REP: 2015).

The renovation projects presented below are aimed at reducing the site's energy consumption.

Projects carried out

Replacement of glazing in a wing of the administrative building

Replacement of single-glazed aluminum frames with double-glazed aluminum frames with thermal break.

Relamping of the manufacturing workshop

Replacement of 921 fluorescent tubes of 120 W each (110 kWh) by 601 LED strip lights of 55 W each (35 kWh).

The expert's opinionThe estimated electricity consumption reduction target for this work is 80 MWh/year (estimate based on 10 hours of lighting per day over 50 weeks of 5 days).

Stéphane Clair, Maintenance and Saftey Manager

Projects under study

Exterior insulation of the administrative buildings

The project is about the reinforced insulation of the administrative buildings frontages, with a thermal coefficient of R=3.70 m²K/W.

The expert's opinion

The estimated electricity consumption reduction target for this work is 56 MWh/year. This represents 25% of the estimated electric heating consumption per year (16% of the total consumption of 2022 – source visite énergie CCI).

Stéphane Clair, Maintenance and Saftey Manager

Reduction of Water Consumption

Installation of a closed-loop circulation system for machines cooling (read article on Ecodesign)

Use of Low-Carbon Energy

REP is examining the possibility of installing photovoltaic panels (estimates are underway).

Solar energy is a clean, renewable source of energy that helps the company reduce its environmental impact while helping to combat climate change.

This will enable REP to save on its energy bill by producing part of the energy needed for its business. Since 2023 this action is already mandatory for the new buildings (climate and resilience law)

- Study for the installation of photovoltaic panels: there are two possible options: either solar canopies on the staff parking lot, or ground-mounted panels with a surface area of around 2,370 m², representing an estimated production equal to 26% of our annual electricity consumption.

- Study for conservation grazing: the idea is to use sheep to limit the use of combustion engines to maintain green spaces.

The Impact of Digital Transformation

Limiting the Use of Paper

Since the migration to the Sylob ERP, the printing and archiving process for many documents has been abandoned, resulting in a significant reduction in paper consumption.

Under study:

- The digital manufacturing workshop project, with the installation of digital workbenches giving operators access to all our drawings, methods documents and ERP.

- The replacement of our PRINT machines with more energy-efficient ones.

The expert's opinion

For example, over a period of one year and a half, around 10,000 orders were placed without needing to be printed or physically archived.

This decision is part of REP's eco-friendly approach for reducing its environmental impact by limiting the use of non-renewable natural resources.

Jean-Christophe Boffet, Digital Transformation Manager

Reduction of carbon footprint related to commutings

- Extension of the sales and service network to be closer to customers and limit travel costs,

- Combining multiple presses into one shipment and using renewable packing materials

- Establishment of teleworking to limit the environmental impact of daily commuting

See our employer brand section

- Training proposals in the form of webinars

- Local Sourcing for a more sustainable supply chain

The objectives

- Reducing the environmental impacts throughout the life cycle of the machines

- Decreasing the energy consumption of the machines

- Using highly recyclable components

Durability of the REP machines

The rubber injection molding machines are well known for their longevity, able to exceed 40 years of use without requiring major replacements on condition that a preventive maintenance is carried out frequently. This feature is highly appreciated by customers, as it enables them to benefit from a long-term return on investment.

The expert's opinion

It is important to mention that we propose a rebuild offer with retrofitting of the switch cabinet for the oldest machines in order to maintain their performance and safety.

This contributes to reducing environmental impact by minimizing the production of waste materials, as well as reducing volatile organic compounds (VOCs).

Jocelyn Dupuy, Group After-Sales Service Manager

Decreasing the Energy Consumption of the Machines

The pre-delivery inspection process includes temperatures control.

This control requires a significant water consumption which is then not recycled. We intend to collect water through the creation of a closed-loop circulation system with cooling through a heat pump.

In winter, the heat generated by the cooling group could be reused for heating.

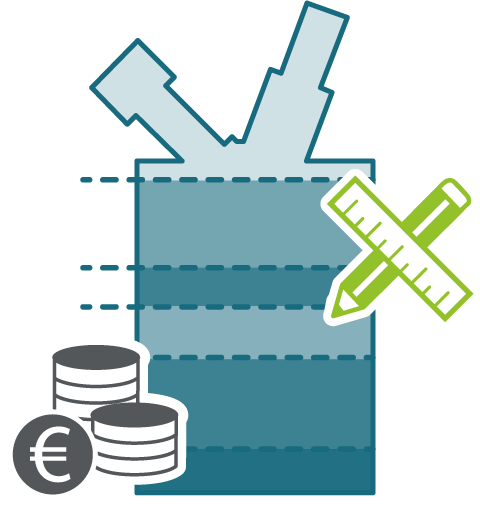

(Re)Design to Cost

The "(Re)Design to Cost" (RTC) concept is an approach aiming at diminishing the production costs by redefining the design of a product or process. REP is adopting this Design to Cost approach for the next generation of machines.

The idea is to reassess the materials and processes related to materials manufacturers, material suppliers and subcontractors.

- Search for less expensive alternative materials offering similar performances or requiring less processing time (e.g. choosing 40CA6-12 steel as alternative for cylinders and pistons),

- Optimization of processes: analysis of the various stages of a process to identify bottlenecks, waiting times or redundant operations in order to reduce costs and lead times while maintaining the required quality(e.g. optimizing the lapping, machining and inspection stages required in the nitriding process for pistons and cylinders)

Solutions for Energy Efficiency

REP develops advanced technologies for saving energy, space and costs

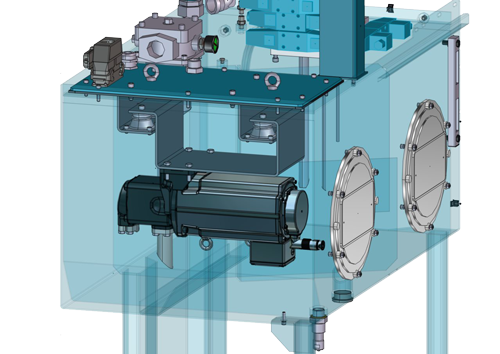

The SDD or SMP solutions for motor and pump drives represented a major technological advance for REP.

The SDD or SMP solutions for motor and pump drives represented a major technological advance for REP.

These solutions allow to reduce drastically the energy consumption: 70% energy savings on presses since their use in 2010, with enhanced reliability and ease of maintenance.

The ServoDive&Drive pump unit (OP276) and the Servo-Motor driven Pump unit (OP270) solutions are optional equipment. They optimize machine energy consumption, helping to reduce production costs and environmental impact.

By adding another option (OP271 energy counter), the customers can also know their exact energy gain via the different energy counters.

Development of Circular Economy

HSM rubber recycling offer

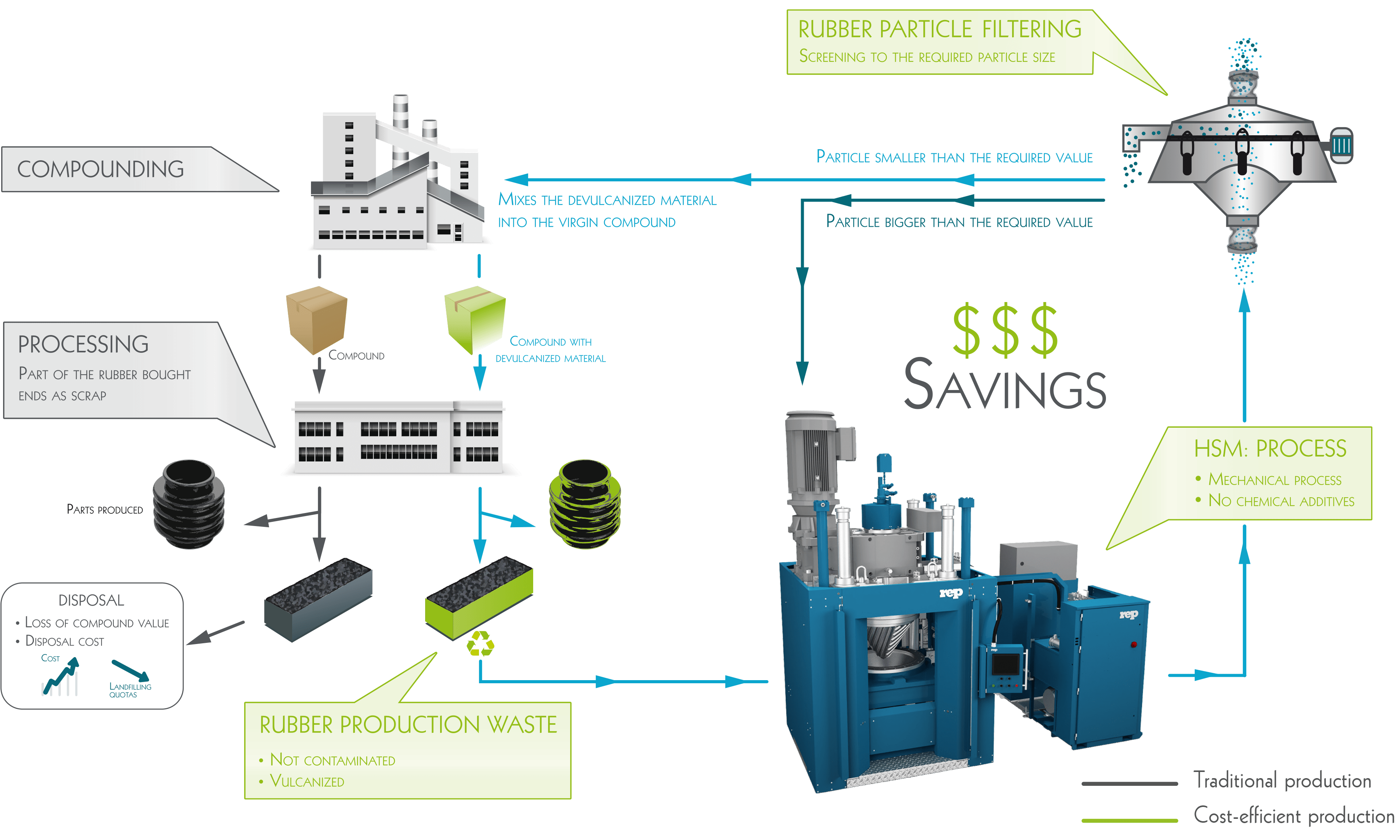

REP has designed a machine using the patented HSM process.

The purpose of HSM (High Shear Mixing) consists in devulcanizing rubber waste and reintroduce it into the production chain.

The expert's opinion

This patented process applies to any kind of uncontaminated rubber production waste. Once the compound is devulcanized, it is reintegrated into the basic compound.

This results in significant savings on both compound and waste disposal costs. This is a 100% thermo-mechanical process without adding any further substances or chemical agents and is performed at low temperature, in order to prevent the characteristics of the devulcanized rubber from being altered.

Rodrigo DIAZ, R&D Process and Application Engineer

Advantages: Reduction of compound costs and elimination of waste disposal costs

Using an Ethics Charter

We plan to ask our suppliers to sign an Ethics Charter (currently being drafted) by which they certify that they adhere to the ethical commitments thus defined. This will answer our customers' concerns about the origin and nature of the components used for their presses.

We created a questionnaire for assessing the presence of Substances of Very High Concern (SVHC) at our usual suppliers' site.

In order to reinforce our commitment to transparency and accountability, we have also decided to include a specific section in our ERP supplier registration form. The purpose of this section is to collect precise information about the possible presence of SVHCs in the products proposed by our suppliers.

REACH and CSR go hand in hand

The REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) as well as the CSR regulation (Corporate Social Responsibility) can be linked while selecting suppliers.

REACH is a EU legislation which aims at improving the protection of human health and environment against the risks related to chemical substances. It coerces companies to register, assess and take appropriate measures for reducing the risks related to the chemical substances used in their products. REACH also encourages companies to substitute the most concerning substances by safer alternatives whenever it is possible.

The expert's opinion

Among the SVHCs mentioned in the feedback received till now, lead appears as one of the most frequently mentioned substances, particularly in the electronics sector (electronic cards for REP). It is important to mention that the use of lead can be justified in some specific applications. However, we highly encourage our suppliers to explore safer alternatives and work closely with the European Chemicals Agency (ECHA) so as to ensure regulatory compliance. Thus, the next technical evolutions for G11 (11th machines generation) will have to take it into account. Managing SVHCs is a challenge, but we are sure that it is possible to adopt practices that respect the environment and health while keeping high quality standards. The goal of our study is to better understand the situation about the SVHCs and take necessary measures for ensuring the safety of the products we propose to our customers.

Fanny Mulas, Supplying and Purchasing Manager

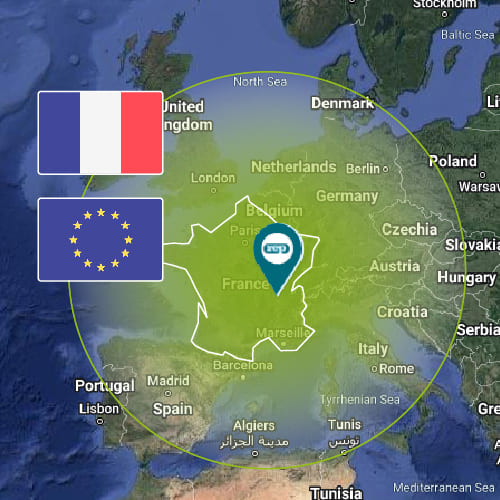

Promoting Local Sourcing

Since the last few years, REP mainly buys its components and raw materials in France and in Europe.

This local sourcing strategy, with almost 90% French suppliers, enables us to reduce CO2 emissions linked to the transport of goods and to promote the local economy by supporting French producers.

This facilitates the relations with the suppliers and ensures a better reactivity in case of need. This strategy is in line with the company's sustainable development objectives et testifies to its commitment in favor of green transition.

Drafting of an anti-corruption guide

Albeit not being specifically related to Corporate Social Responsibility (CSR), it can have significant implications in this field.

The greater protection for whistleblowers encourages the reporting of misconduct, which can help promote ethical and responsible practices within organizations.

We have drafted an anti-corruption guide for our staff and partners.

The expert's opinion

As far as CSR is concerned, the Loi Sapin II can have a significant impact on companies by encouraging them to adopt transparency and responsibility behavior. By strengthening anti-corruption obligations and promoting the introduction of preventive measures, the law encourages companies to implement socially responsible policies and practices.

Gabriel Sagne, Finance and Accounting Deputy Director