Main Options for Your Press

Which Options for my Rubber Injection Press?

Optional equipment

REP rubber injection molding presses can be adapted to meet all the requirements and constraints specific to your type of production. You can choose from among different standard options :

Hydraulic Ejectors designed to synchronize several opening levels

Two side guiding rods connected through a rack and pinion system achieve synchronization. This system provides an efficient mechanical synchronization.

Two side guiding rods connected through a rack and pinion system achieve synchronization. This system provides an efficient mechanical synchronization.

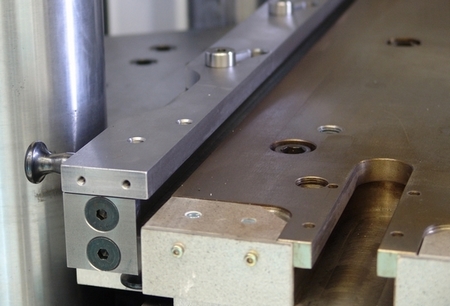

Quick-latch System changes

Rapid mold change even when the mold is hot.

Rapid mold change even when the mold is hot.

Sliding platen (for vertical rubber injection presses) for easier access

These facilitate access to the lower part of the mold and manual de-molding operations.

These facilitate access to the lower part of the mold and manual de-molding operations.

Automated production (for vertical rubber injection moulding machines) with stripping kits to reduce the cycle time.

Sturdy, modular universal kits for vertical presses. They can be fitted with brushes for cleaning the cavity plates and devices which allow the use of double plate moulds or double lower moulds for demoulding parts in hidden time.

Sturdy, modular universal kits for vertical presses. They can be fitted with brushes for cleaning the cavity plates and devices which allow the use of double plate moulds or double lower moulds for demoulding parts in hidden time.

Adjustable brushes on horizontal rubber injection molding machines

The position of the brushes can be adjusted to suit the clearance between the two mold plates. The brushes can be used after each cycle to clean the mould surfaces or to facilitate parts stripping.