Composite Molding Presses

Molding of non-rubber materials

Thermoset and Composite Molding

Did you know REP also supplies composite molding presses?

The composite materials sector is booming

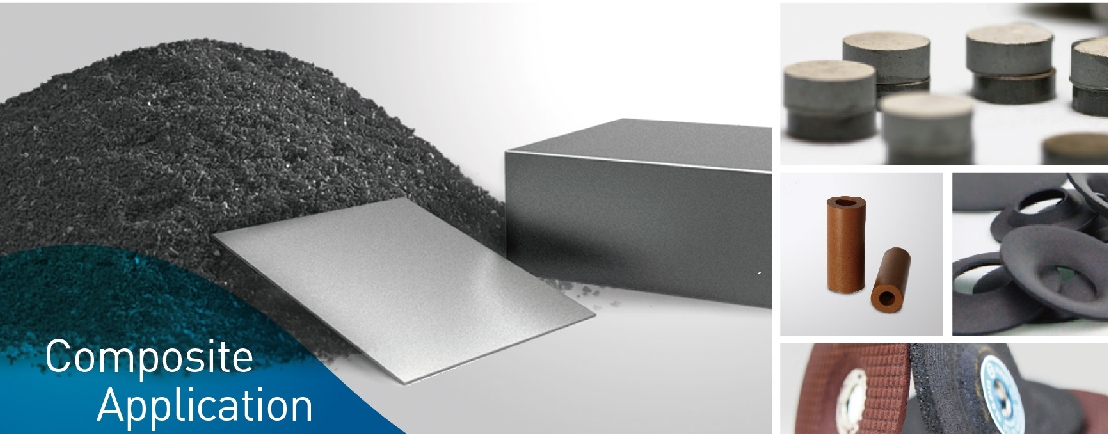

Composite materials were originally used in the aircraft industry, but they gradually reach into every mass production sector. They have many and varied applications, such as:

- automotive industry (body panels, engine hoods)

- electric industry (connectors made of thermosetting materials),

- sanitary industry (toilet seats and covers),

- household appliances (irons),

- sport and leisures (bicycle parts, tennis rackets).

Composite molded parts are light-weight shock-proof and corrosion-resistant parts. Despite their big size, they are extremely steady and stable.

BMC or SMC are materials with many qualities

Composite materials, for instance PDCPD (polydicyclopentadiene), BMC (Bulk Molding Compound), SMC (Sheet Molding Compound) - are polyester-resin-based thermoset compounds, reinforced with glass or carbon fibers, fillers and various additives. The resin may be pre-preg.

Composite materials, for instance PDCPD (polydicyclopentadiene), BMC (Bulk Molding Compound), SMC (Sheet Molding Compound) - are polyester-resin-based thermoset compounds, reinforced with glass or carbon fibers, fillers and various additives. The resin may be pre-preg.

Compared to traditional materials, composite materials offer many advantages thanks to their chemical, thermal and electrical properties.

The main processes used for forming composite parts are BMC compression molding, SMC compression molding, RIM injection ("Reaction Injection Moulding") and RTM injection ("Resin Transfer Moulding").

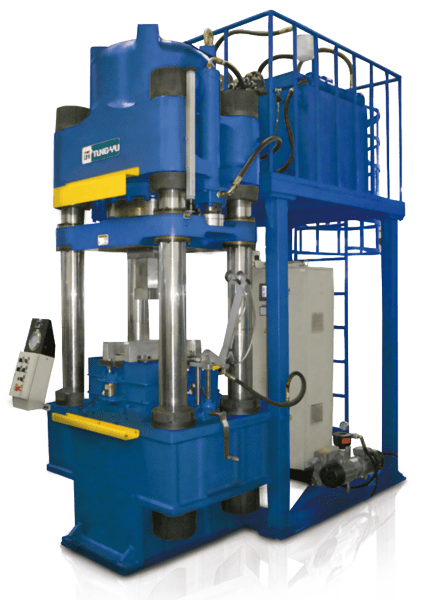

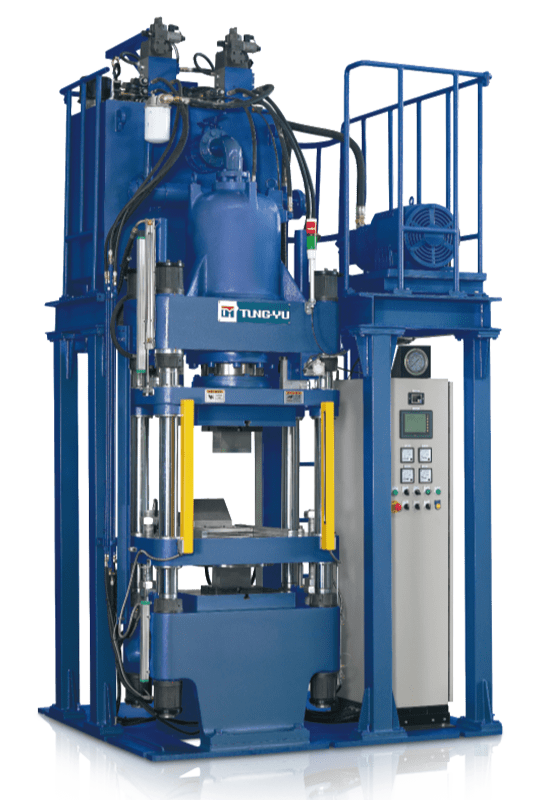

Manufacturers of hydraulic presses adapt to the composites market

Composite and thermoset materials have a low viscosity thus implying mold heating, but they do not require high pressures. This permits using compression presses with much larger platens.

As Stewart Knight, sales manager in charge of the commercialization of TUNG YU's presses at REP, tells us, "all we need is a press that provides heat and pressure! And that's exactly what Tung Yu is doing well".

The REP group has been successfully distributing for 10 years the compression presses made by their Taiwanese partner TUNG YU whose offer is 80-percent customized.

Vacuum compression molding, hot-cold presses, sandwich molding, presses to mold friction parts, presses in clean rooms, etc., TUNG YU has broad and diverse experience as evidenced here by a customer with very unusual specs: a compression press with a closing force of 250 tons with platens of 3m x 4m and an opening stroke of 3.20 m, which tilts to 25°.....while the mold continues to be heated up.

You may like our videos of compression presses on our YouTube page too.

Best placed to understand your needs, REP is there to listen to your project and provide you in partnership with Tung Yu with solutions for molding composite and non-rubber materials. Our offer ranks quite well with a competitive quality/service/price ratio.