Eco-Design and Energy efficiency

Isothermould®

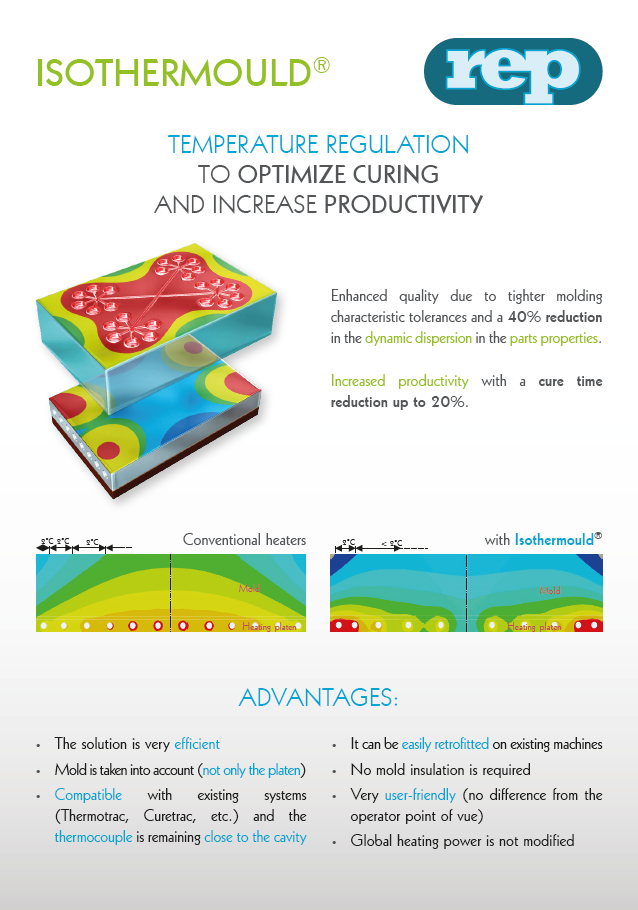

Optimal power distribution on heater plates

The Issue: Heat is not evenly distributed within a mold.

This results in heat loss between the center and the edges of the mold. Uneven temperatures and a volatile cure time have a negative impact on part quality and on production overall.

Heat distribution is a crucial factor for both:

- Flows and balanced filling of the mold

- Curing conditions (cure time and part characteristic variances)

The Solution: Improve temperature homogeneity

REP provides a system that reduces temperature variations, and therefore:

- Reduces cure time

- Reduces flash and improves balancing

- Improves the quality of parts

What our expert says

Isothermould® technology compensates for heat dispersion at the edges of the mold in order to control the thermal imbalance of the heater plates. This gives us optimal heat distribution and balancing within the mold.Thermal variations can be maintained at between 1.5° and 3°C whereas without Isothermould®, we are more likely to see differences of between 5° and 10°C.

This means a 40% reduction in parts characteristic variances and a 20% reduction in cure time with no change to the overall heating power.

Matthieu Wolff, Process Development Engineer

How does Isothermould®’s principle of heat distribution work?

Invisible to the operator, the system is located in the heater plates. The Isothermould® solution consists of one temperature control area per heater plate and the use of distributed power rods.

The effectiveness of the concept is reproducible and does not rely on the settings applied at mold set-up.

Adaptable technology

Isothermould® is compatible with existing injection presses, regardless of their size or number of cavities in the molds.

Proven effectiveness

REP has proven its solution using large machines with precise specifications.