CMX

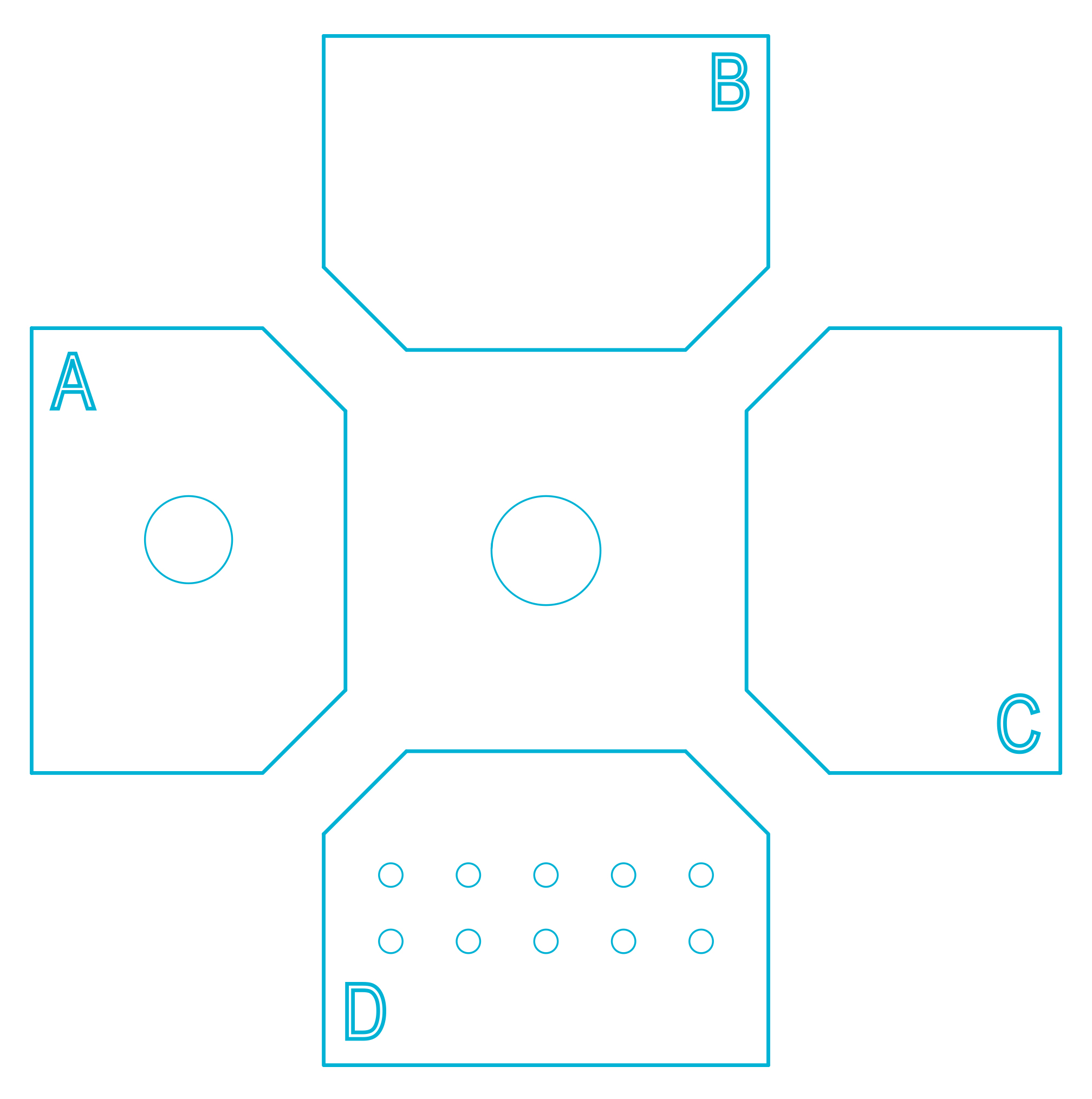

The CMX1 is a rotary four-station press available as standard with a Y1000 or Y2000 or Y5000/L5000 injection unit.

Main advantages

90% increase in productivity compared with a single-station press.

CMX1 Y1000

- Clamping force: 1540/502/502/- kN

- Dimensions of heater plates: 510 x 360 mm

- Injection capacity: 1000 cm3

- Injection pressure: 1500 bar

- Width x depth: 3060 x 1620 mm

- Height: 3860 mm

CMX1 Y2000

- Clamping force: 1540/502/502/- kN

- Dimensions of heater plates: 510 x 360 mm

- Injection capacity: 2000 cm3

- Injection pressure: 1500 bar

- Width x depth: 3060 x 1620 mm

- Height: 4202 mm

CMX1 Y5000/L5000

- Clamping force: 1540/502/502/- kN

- Dimensions of heater plates: 510 x 360 mm

- Injection capacity: 5000 cm3

- Injection pressure: 1500 bar

- Width x depth: 3060 x 1620 mm

- Height: 4802 mm

The CMX2 is a rotary multistation machine available as standard with a Y1000 or Y2000 or Y5000/L5000 injection unit.

Main advantages

68% increase in productivity compared with a press equipped with a double plate stripping kit.

CMX2 Y1000

- Clamping force: 2544/785/785/- kN

- Dimensions of heater plates: 630 x 500 mm

- Injection capacity: 1000 cm3

- Injection pressure: 1500 bar

- Width x depth: 3705 x 2120 mm

- Height: 4160 mm

CMX

CMX2 Y2000

- Clamping force: 2544/785/785/- kN

- Dimensions of heater plates: 630 x 500 mm

- Injection capacity: 2000 cm3

- Injection pressure: 1500 bar

- Width x depth: 3705 x 2120 mm

- Height: 4500 mm

CMX2 Y5000/L5000

- Clamping force: 2544/785/785/- kN

- Dimensions of heater plates: 630 x 500 mm

- Injection capacity: 5000 cm3

- Injection pressure: 1500 bar

- Width x depth: 3705 x 2120 mm

- Height: 5100 mm

CMX

Take a look at its many advantages!

Cure time reduction achieved through:

- high compound temperature inside the injection unit

- high mould temperature

- High ratio between closing force/plate dimensions

Strong thermal stability of the process:

- small moulds with few cavities

- short and stable mould opening time

Great flexibility:

- Quick mold change (10 min for 4 molds)

- possibility to disable a mould

- possibility to program different shot sizes

- Possibility to install stripping kits

Ergonomics

- ergonomic configuration for operator or robot (automation facility)

- reduced space requirement of the machine

See a demo of rotary multistation injection molding

Download the flyer:

CMX Range: Multistation Presses

CMX

New generation of 4-station molding machines

This new machine replaces the former CMS generation and makes the third generation of rotary machines with 2 major innovations:

- Integration of the process-control system of the latest generation (generation 10) with all 4.0 functions.

- Product range with the CMX1 (160T clamping force) and the CMX2 (250T clamping force).

The REP solution for large productions with optimal efficiency

Main advantages

- 90% increase in productivity compared with a single-station press.

- 68% increase in productivity compared with a press equipped with a double plate stripping kit.

The CMX machine is available with two clamping forces:

160T (CMX1) or 250T (CMX2)

Take a look at the many advantages of the CMX! (video)

Download the flyer:

CMX Range: Multistation Presses