Insulator molding

Special Presses

Do you need a giant molding machine?

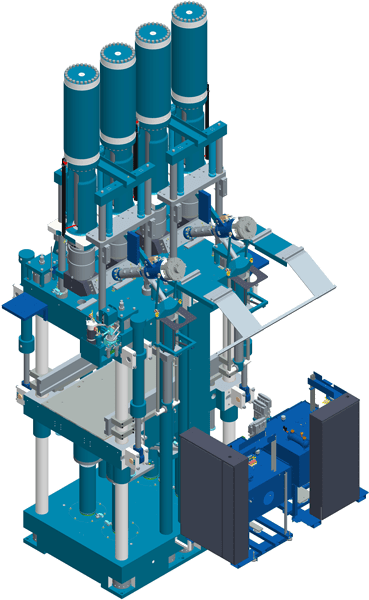

The S24 beats all records!

Designed for the manufacture of high-voltage insulators (550 kV), this is one of the largest presses made by REP.

The dimensions of the parts to be injected explain the huge size of the press: 660 mm in diameter, 2,600 mm long, moulded in one go.

The production of a complete insulator takes place, therefore, in between one and four cycles, significantly increasing productivity and the reliability of parts.

The S24 exists in two versions: L50 or L100

S24

- Clamping force: 24,000 kN

- Dimensions of heater plates: 1500 x 3000 mm

- Injection capacity: 25,000 cm3 x 2 (2 injection units)