REP Key Dates

2022

EPG Horizontal Range

ECOTRONIC compact electric rubber injection molding machine

2022

2018

CMX: The CMS in version G10

Multistation machine with latest-generation PLC. Available in two clamping forces (160T or 250T)

2014

G9A range

REP's expert know-how on the Asian market

2014

2013

G10 range: Intelligent, elegant and efficient

A double wink to its new ergonomic design and its embedded intelligent solutions, the G10 generation is branded "Infinitely Smart".

2008

CMS: Compact Multi Station

Unique multistation design for maximum productivy, particularly suitable for rubber metal parts

2008

2007

Turbocure®

Up to 50% cure time reduction and higher quality parts. This device consists of two independent modules: TempInverter® and FillBalancer®

Company's anniversary

CELEBRATING 100 YEARS!

Company's anniversary

2004

G9 Range

Time saving for change in production and dry cycle times: new records. The G9 range is controlled via a touchscreen with extremely comprehensive features.

1978

G4 Range

Switch cabinet with PLC and adjustment of strokes, speeds and pressures by potentiometers.

Centralized, computerized, self-correcting management of the injection process. Closed-loop regulation of speeds, pressures and temperatures.

1978

1964

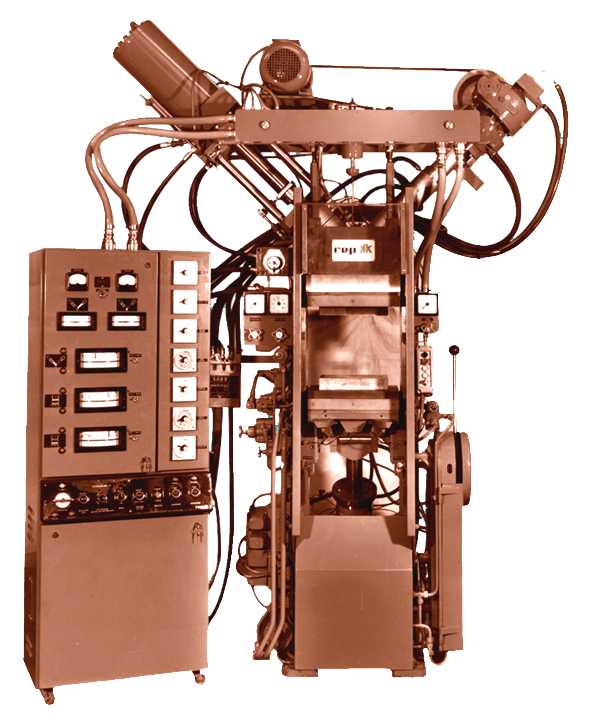

G1 Range

Injection unit with separate plasticization and injection functions and water regulation. Vertical press with a mechanically welded toggle lock closure operated by a 2-stroke hydraulic mechanism. Manual operation via actuated lever.

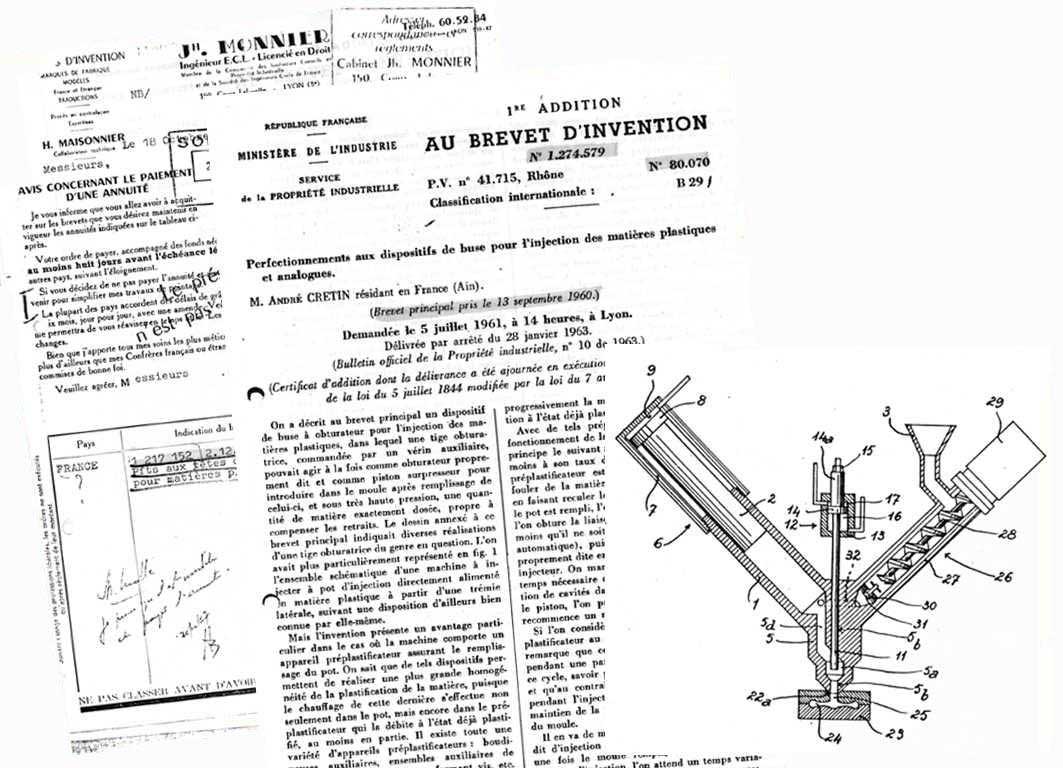

1961

Injection unit tailored to rubber injection

Patented V head no. 1961 070/1 274 579.

Thanks to this design of the injection unit with separate injection and plasticization functions, REP develops technology tailored to rubber injection.

1961

1948

First plastic injection molding machine marketed by REP

1907

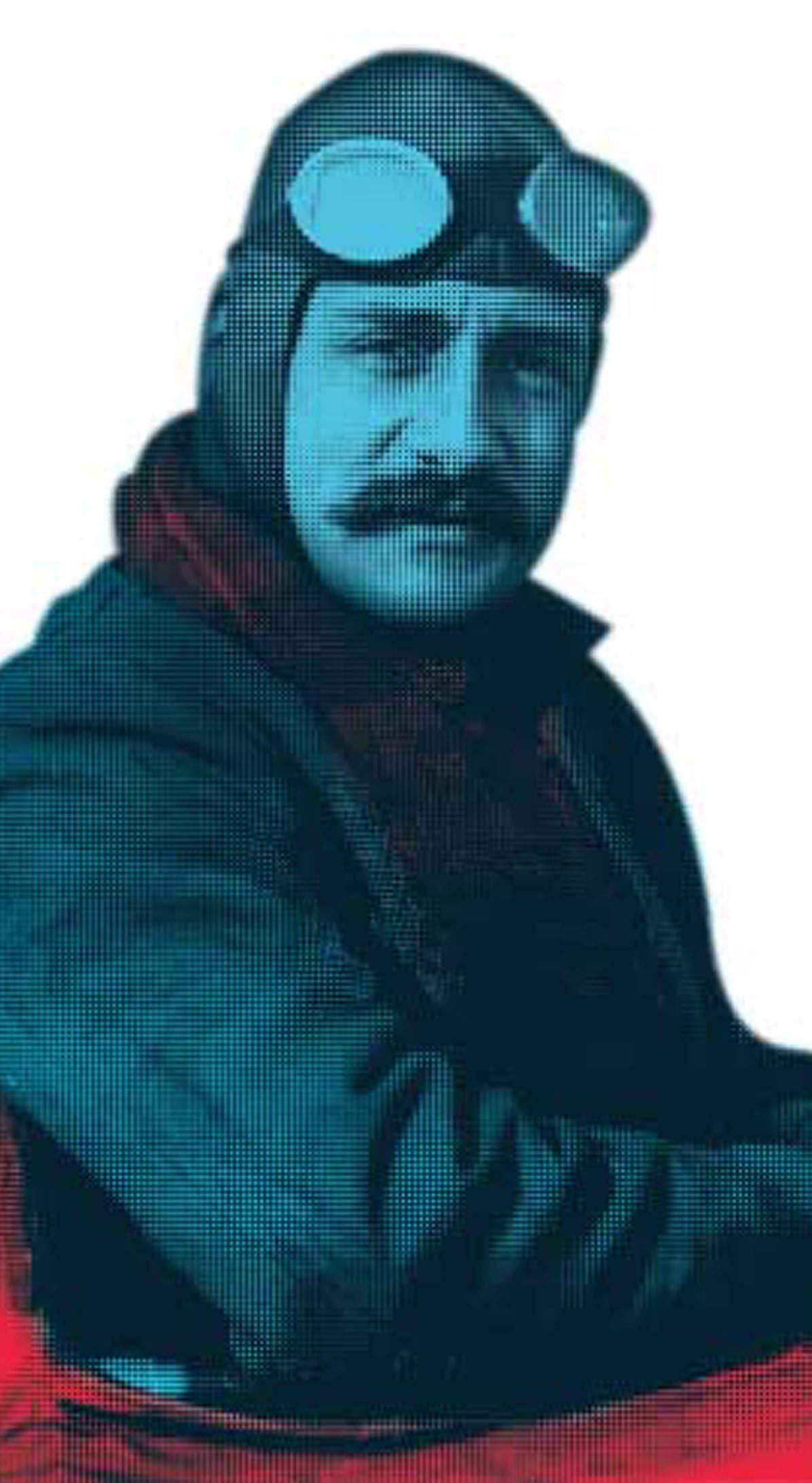

Robert Esnault Pelterie

REP was founded by Robert Esnault Pelterie (R.E.P.), an aviation pioneer and a major theorist in the field of astronautics, in 1907.

1907