News Feeds

Wayne Rubber: mastering rubber, from formulation to finished product

Tell us about yourself

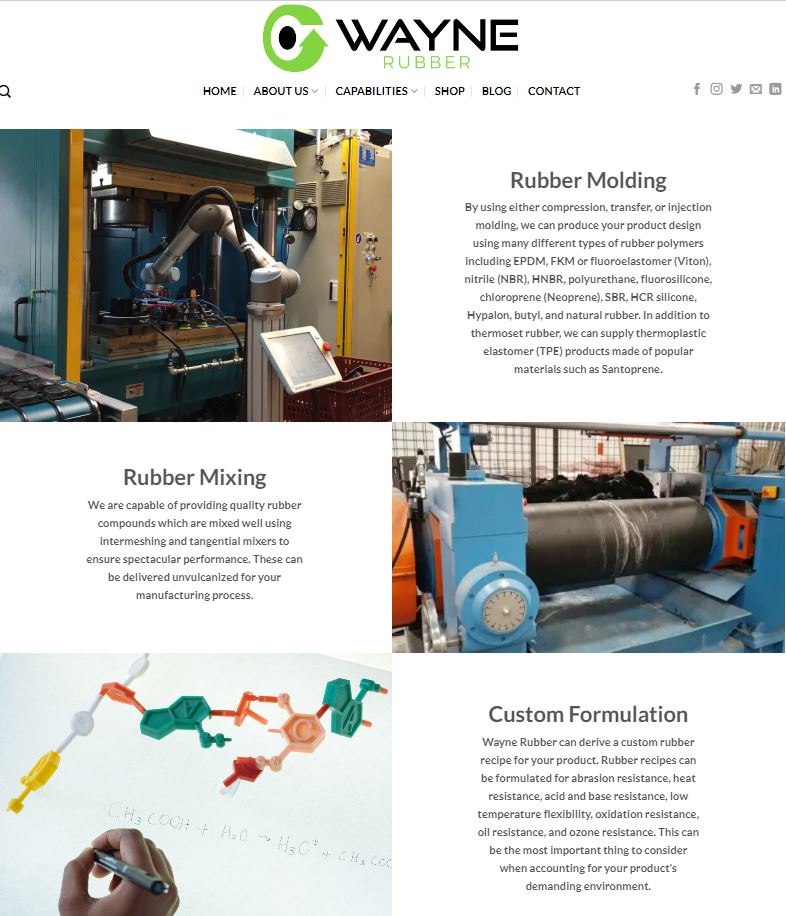

- Wayne Rubber is a manufacturer and distributor specializing in molded rubber products, from compound formulation to the finished product.

- We are experiencing continuous growth thanks to a strong commitment to quality, reliability, and customer satisfaction.

- We support our customers with a extensive technical expertise.

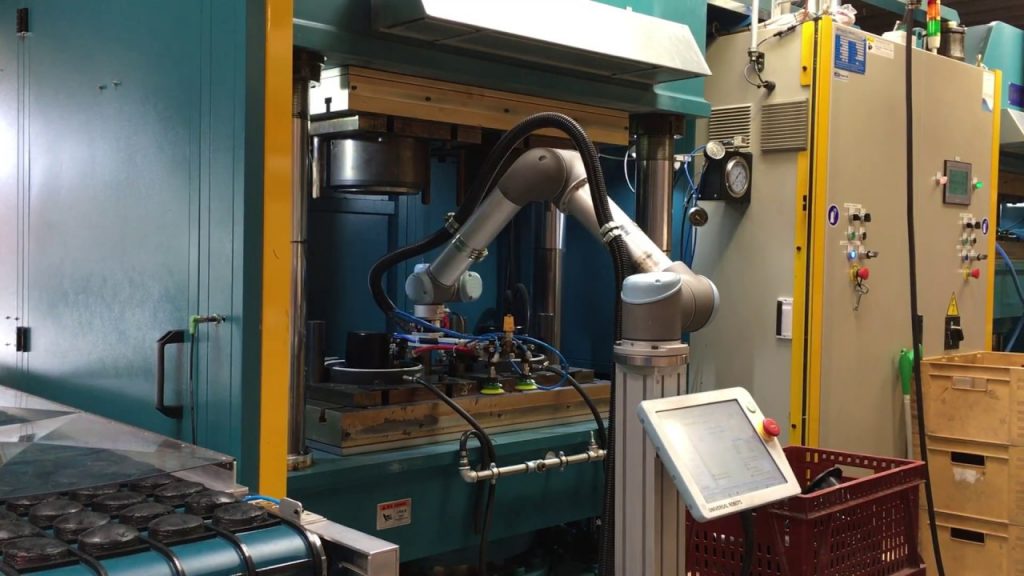

Focus on your workshop

REP: How many REP presses do you have in your plant?

Wayne Rubber: We currently have two REP injection molding presses, installed in our brand-new factory recently opened in Wixom:

- A V710 Core (G10 generation), equipped with an L50 injection unit, and with a clamping force of 500t.

- A V67 (G7 generation from the 1990s), with a clamping force of 400t.

These machines are extremely accurate, offering perfect repeatability and optimal flexibility.

REP: How did the installation and integration process for your new presses go?

Wayne Rubber: Everything went smoothly. From delivery to start-up, REP’s technical staff demonstrated great professionalism.

The training sessions were extremely thorough, helping our operators and engineers quickly gain confidence in :

- machine setup

- maintenance

- and process optimization.

REP: Which technical or ergonomic aspects do you particularly appreciate?

Wayne Rubber: Our teams appreciate that REP presses are designed with the operator in mind, in order to minimize downtime and simplify setup.

Three notable points:

- The simple and user-friendly control interface

- Consistent temperature and pressure regulation

- Ergonomic access to all machine components

Data tracking and automation features contribute to process traceability, which is a key priority for us.

Focus on your production

REP: Have you ever encountered the machine's capacity limitations?

Wayne Rubber: Not at all. We have processed a wide variety of materials, including EPDM, NBR, SBR and special elastomers, with excellent results.

REP machines maintain stable temperatures and injection pressures, enabling clean and uniform parts.

REP: What is the advantage in terms of productivity?

Wayne Rubber: The REP machines have been a game changer in productivity! Their fast cycles and controlled energy consumption, have enabled us to maintain high efficiency without sacrificing quality. Repeatability between cycles minimizes scrap and rework, allowing us to focus on throughput and reliability.

Operator feedback has been extremely positive : setup and operation are intuitive, which helps us maintain our productivity even when we are training new staff!

Focus on your finished product

REP: In your opinion, what defines a high-quality piece?

Wayne Rubber: For us, a high-quality part is one that retains its dimensional accuracy, surface finish, and performance consistency across large production runs.

We define quality not only by meeting specifications, but by producing parts that perform reliably in the field over time.

REP: How do your part and services stand out from the competition?

Wayne Rubber: We differentiate ourselves through a combination of :

- Engineering support,

- Expertise in materials and mixing,

- Constant collaboration with our customers.

We don’t just mold parts - We work closely with our customers to optimize materials, design, and processing, ensuring that the final product delivers optimal performance for its intended use.

REP: Is the optimization of the waste rate and material scrap a concern for you? How does your product answer these issues?

Wayne Rubber: Yes, waste reduction is a major focus. The consistency and repeatability of REP presses have allowed us to reduce start-up scrap and optimize material usage.

This aligns with both our environmental goals and our customers’ cost expectations.

REP & you

REP: What made you come to REP more than to any other company?

Wayne Rubber: it's REP's reputation for technical excellence, reliability, and customer service. We evaluated several other press manufacturers, but the technical capabilities, robust press design, and proven experience record of the company in the field made REP the obvious choice!

Engineering excellence

Reliability

Customer service

REP: What were your main constraints, and are you satisfied with the results?

Wayne Rubber: Our main constraints were footprint and flexibility. We needed machines that were compatible with a wide range of mold sizes and capable of processing all kinds of materials within a compact layout.

REP presses have exceeded our expectations in both respects. We're extremely satisfied with their performance and the support we've received.

Our experience has been overwhelmingly positive! The machines have delivered on all their promises, and our partnership with the REP team has proven to be very collaborative and supportive. It's a relationship based on mutual respect and a shared commitment to excellence.

Your future projects

REP: What are your future goals and challenges to complete?

Wayne Rubber: The next step for Wayne Rubber is to develop our in-house molding capabilities and continuing to grow our customer base in high-specification markets such as automotive and industrial OEMs.

We are also investing in testing and R&D capabilities to better meet our customers' needs. As we grow, REP equipment will continue to play a central role in our production strategy.

Wayne Rubber recommends REP's machines, teams, and services with an excellent rating of:

.JPG)

.jpg)