Composite Molding Presses

Thermoset and Composite Molding

Stunning! A press which tilts to 25°.....while the mold continues to be heated up

Very special specs:

- A machine of 8,400 mm height

- Clamping force: 2500 kN

- Plates: 3 m x 4 m

- An opening stroke of de 3.20 m

- The press tilts while the mold continues to be heated up

- A shuttle table

- A 2m deep pit.

The biggest press of this type in the world

Mr Roland PERROLLIER, Industrial Manager of the COURBIS Group witnesses as follows:

"We submitted our specification for a very specific press intended for the molding of site vehicle engine hoods of 2 m x 1 m x 1 m and 30 kg.

Considering the complexity of the parts at low-pressure injection and a relatively low closing force, the press needed to "tilt" to let the flue gas exit through the parting line and allow for optimized filling and a bubble-free part.

After several project reviews following the discussions with the engineers of REP and Tung Yu, the press was ready within the deadlines defined. During the FAT at Tung Yu, we could run the tests with our own mold and discover its operation far beyond our expectations, mainly in terms of process control. The press was shipped with its accessories without any problem.

Installed and commissioned in January 2014, our local technicians could easily get familiar with thanks to the simplicity of its controls and the memorization of the molding parameters. Very satisfied, we turned again toward REP for our next step, the production in Brazil."

Thermoset and Composite Molding

An implementation in the sanitary industry

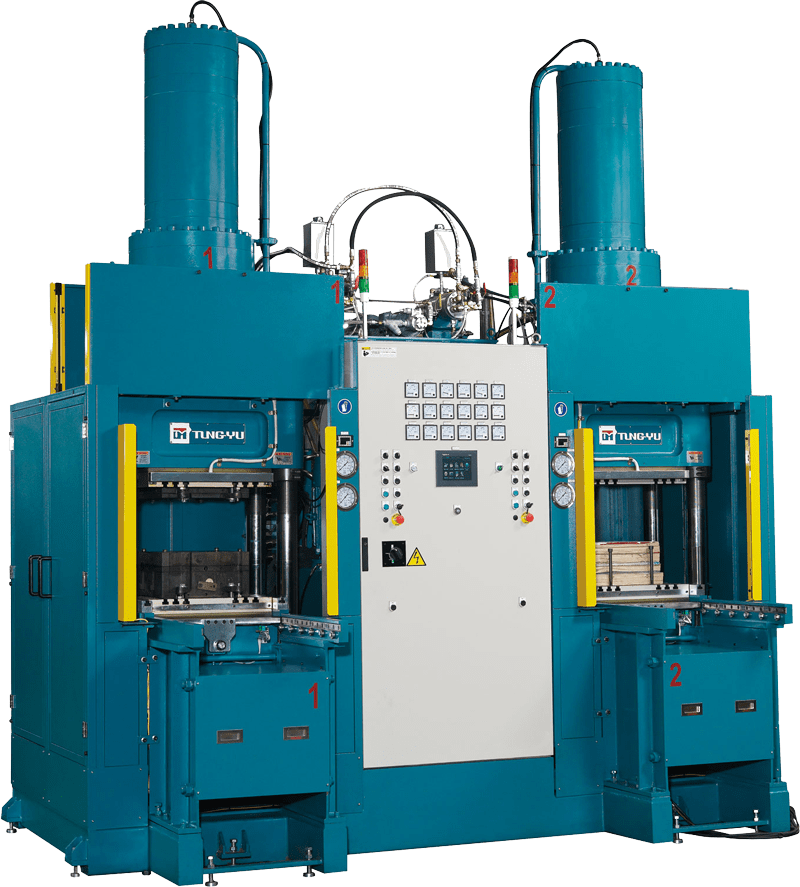

Compression presses in semi-cleanroom at Dubourgel-Grange's plant (France)

The company Dubourgel-Grange based in Fontaine, France, is known for the quality of their range of sanitary articles.

The production facility is equipped with a large pool of presses from 400 to 6000 kN clamping force with manipulators and robots.

In 2009, Tung Yu compression presses were supplied by REP, among which three double-station TYC-22 presses.

- Clamping force: 5000 kN

- Plates: 800 mm x 800 mm.

These machines are used to produce high-end toilet covers and seats made in thermoset resin (urea-formaldehyde).

They are fully automated (loading and unloading robot) and operate round the clock, and often 7 day/weeks.

Thermoset and Composite Molding

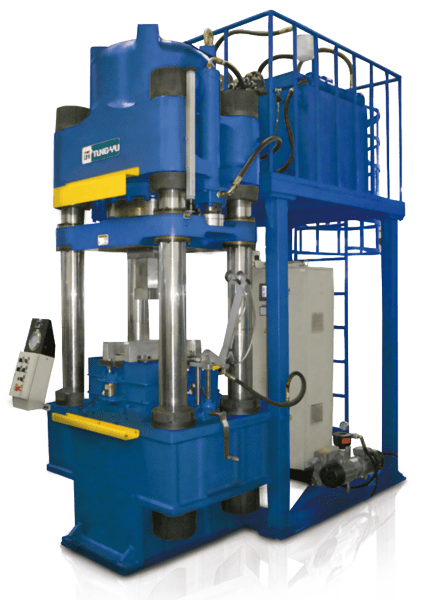

Bridge-type compression press TPS-2000-A-PCD

Clamping force: 20000 kN

Specific pressure 500 kg/cm²

Dimensions of heater plates: 1500 x 1500 mm

Minimum mould closing speed: 0.03 mm/s

Also available in a 10,000 ton version!

Implementation examples: We supplied to a Korean manufacturer of large television screens a machine with platens of 2,800 mm x 1,600 mm for which we obtained a parallelism of 0.05mm.

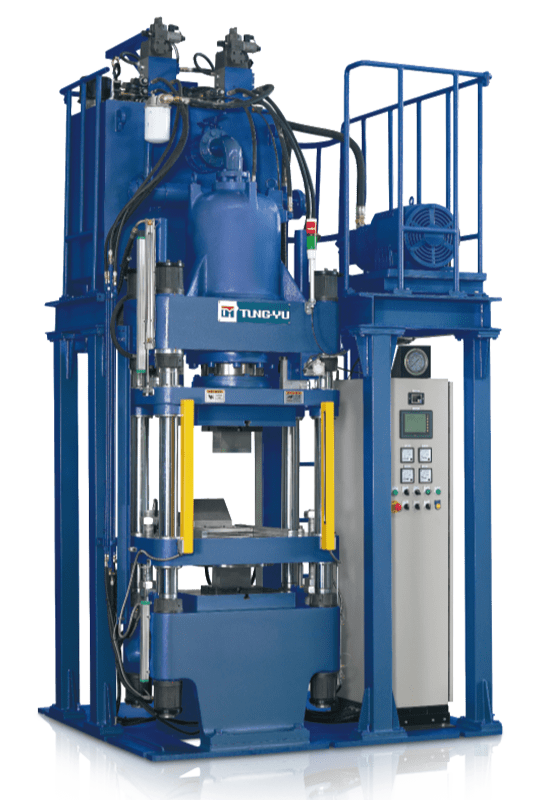

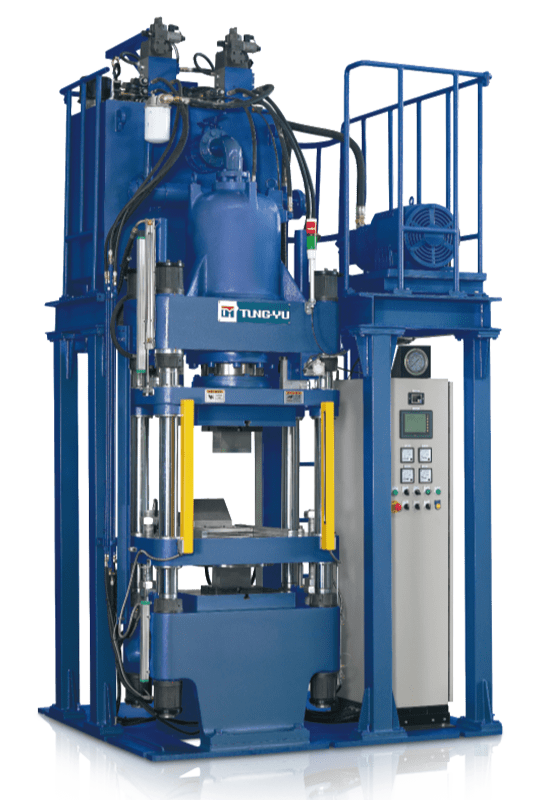

Hydraulic compression molding machine TYC-12-S-PCD-2L-UP

Clamping force: 1500 kN

Closing from the top

Specific pressure 600 kg/cm²

Safety: light curtain, dual-hand control

Available as single-deck or double-deck machine

Implementation examples: dielectric resonator

Hydraulic compression forming machine for abrasive materials TYC-22-PCD-UP

Clamping force: 5000 kN

Closing from the top

Specific pressure 2600 kg/cm²

Bottom ejection battery

Implementation examples: brake pads, clutch disks, powder metal parts

Multideck hot/cold forming press TPS-200-PCD-3L

Clamping force: 2000 kN

Available also as double station , triple station or multistation.

Hot cold process for carbon or glass fiber applications.

Implementation examples: carbon bicycle forks

Compression and transfer molding for thermoset parts

Clamping force: 2000 kN

Implementation examples: connector parts, pharmastoppers

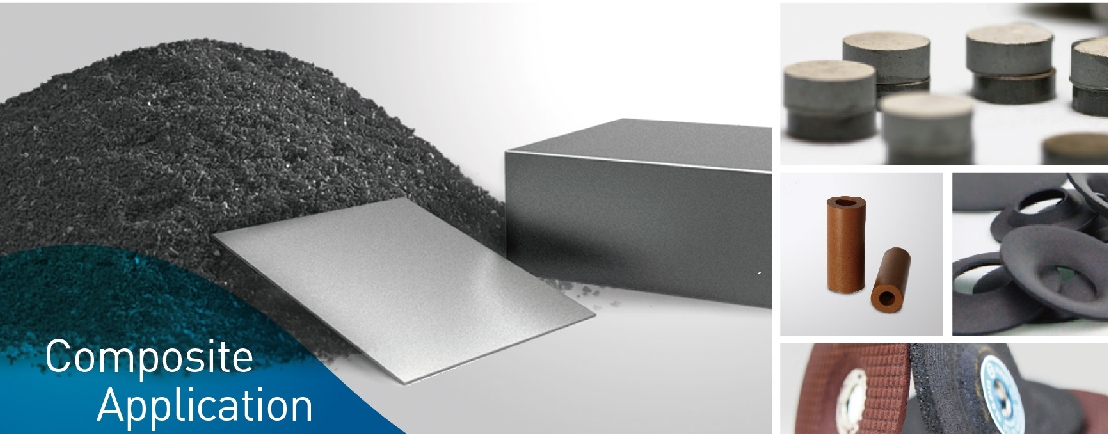

Thermoset and Composite Molding

Did you know REP also supplies composite molding presses?

The composite materials sector is booming

Composite materials were originally used in the aircraft industry, but they gradually reach into every mass production sector. They have many and varied applications, such as:

- automotive industry (body panels, engine hoods)

- electric industry (connectors made of thermosetting materials),

- sanitary industry (toilet seats and covers),

- household appliances (irons),

- sport and leisures (bicycle parts, tennis rackets).

Composite molded parts are light-weight shock-proof and corrosion-resistant parts. Despite their big size, they are extremely steady and stable.

BMC or SMC are materials with many qualities

Composite materials, for instance PDCPD (polydicyclopentadiene), BMC (Bulk Molding Compound), SMC (Sheet Molding Compound) - are polyester-resin-based thermoset compounds, reinforced with glass or carbon fibers, fillers and various additives. The resin may be pre-preg.

Composite materials, for instance PDCPD (polydicyclopentadiene), BMC (Bulk Molding Compound), SMC (Sheet Molding Compound) - are polyester-resin-based thermoset compounds, reinforced with glass or carbon fibers, fillers and various additives. The resin may be pre-preg.

Compared to traditional materials, composite materials offer many advantages thanks to their chemical, thermal and electrical properties.

The main processes used for forming composite parts are BMC compression molding, SMC compression molding, RIM injection ("Reaction Injection Moulding") and RTM injection ("Resin Transfer Moulding").

Manufacturers of hydraulic presses adapt to the composites market

Composite and thermoset materials have a low viscosity thus implying mold heating, but they do not require high pressures. This permits using compression presses with much larger platens.

As Stewart Knight, sales manager in charge of the commercialization of TUNG YU's presses at REP, tells us, "all we need is a press that provides heat and pressure! And that's exactly what Tung Yu is doing well".

The REP group has been successfully distributing for 10 years the compression presses made by their Taiwanese partner TUNG YU whose offer is 80-percent customized.

Vacuum compression molding, hot-cold presses, sandwich molding, presses to mold friction parts, presses in clean rooms, etc., TUNG YU has broad and diverse experience as evidenced here by a customer with very unusual specs: a compression press with a closing force of 250 tons with platens of 3m x 4m and an opening stroke of 3.20 m, which tilts to 25°.....while the mold continues to be heated up.

You may like our videos of compression presses on our YouTube page too.

Best placed to understand your needs, REP is there to listen to your project and provide you in partnership with Tung Yu with solutions for molding composite and non-rubber materials. Our offer ranks quite well with a competitive quality/service/price ratio.