REP Basics

A high-performance system to produce rubber parts with consistency and accuracy

What is “flash”?

When a part is molded, excess material attached to the molded part is called flash or flashing.

It is typically caused by system deformation due to the closing force of the platens and traverses:

Learn the basics about REP injection molding process!

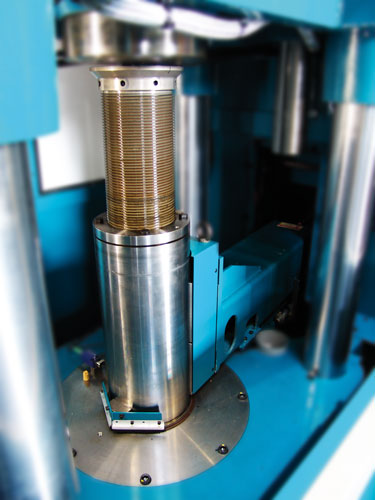

Want to learn more? Close-up on REP injection units

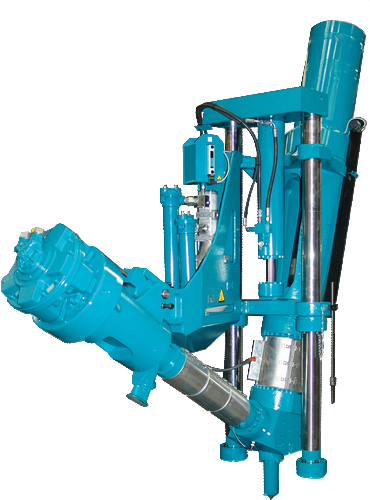

Three-stage closing: long production run reliability

With the 160 to 800 ton presses and over (1200 and 2000 tons), rapid closing is ensured by two hydraulic cylinders.

A pivoting indexing block inserts itself between the movable traverse and the mold adjusting screw.

The strong point of REP injection: it simply has no weak points.

The strong point of REP injection: it simply has no weak points.

The design of the REP injection unit enables elastomers within a large range of viscosity and hardness to be easily fed and injected. This is without equal on the market.