REP international : A World Leader in Rubber Machinery

The REP company has been selling injection molding machines since 1948. Very early on, REP understood the importance of polymers and elastomers to industry and decided to specialize in the rubber injection technology.

Key Events and Dates of REP's History

Our advantages ?

"Exclusive solutions and an international network of sales and aftersales agents"

Our core know-how?

"A high-technology range of vertical and horizontal rubber injection molding machines"

Our motto

"Rubber in Motion"

Our philosophy

"Using new ideas to achieve sustainable productivity"

... and before that?

Founded in 1907 by Robert Esnautlt Pelterie, an aviation pioneer and a major theorist in the field of astronautics, the initials REP were first used as a plane logogram until the company turned to the metal industry.

Want to learn more?

Read the book "Robert Esnault-Pelterie, du ciel aux étoiles, le génie solitaire" (From sky to the stars, a solitary genius) by Félix Torres and Jacques Villain (Publisher: Confluences Editions)

More than 115 years of innovation !

REP was founded by Robert Esnault Pelterie (R.E.P.), an aviation pioneer and a major theorist in the field of astronautics, in 1907.

1948

First plastic injection molding machine marketed by REP.

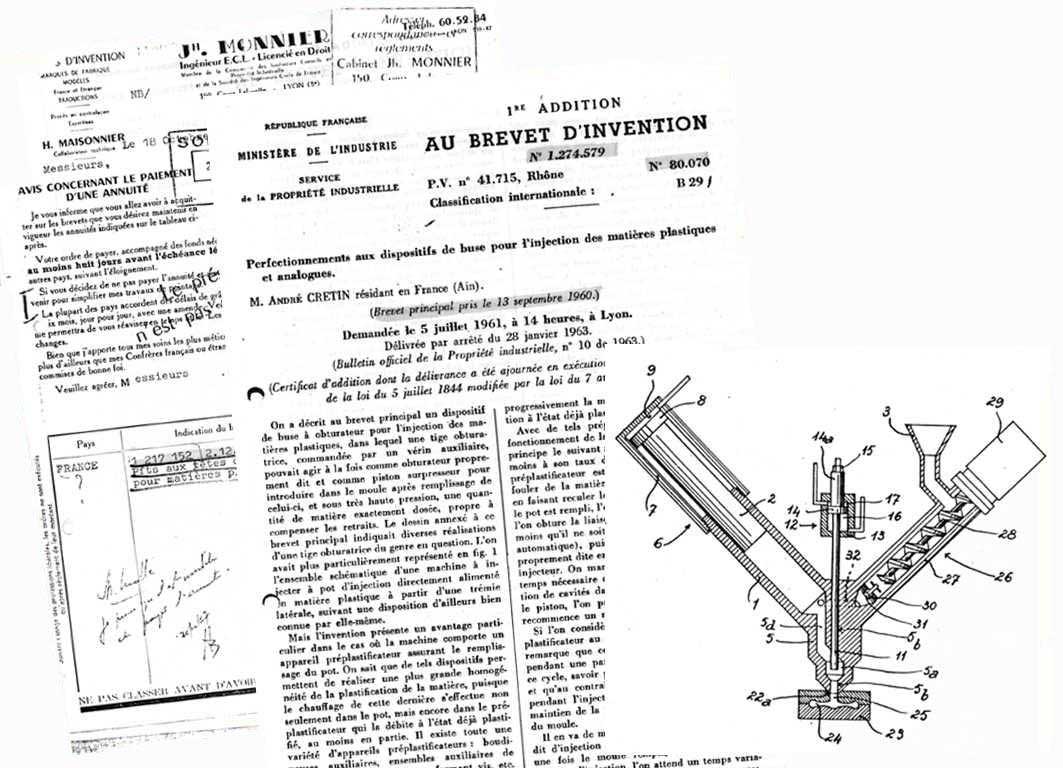

1961Patented V head no. 1961 070/1 274 579.

Thanks to this design of the injection unit with separate injection and plasticization functions, REP develops technology tailored to rubber injection.

1964

G1 range of rubber injection molding machines

Injection unit with separate plasticization and injection functions and water regulation. Vertical press with a mechanically welded toggle lock closure operated by a 2-stroke hydraulic mechanism. Manual operation via actuated lever.

1978

G4 range of rubber injection molding machines

Switch cabinet with PLC and adjustment of strokes, speeds and pressures by potentiometers.

Centralized, computerized, self-correcting management of the injection process.

Closed-loop regulation of speeds, pressures and temperatures.

1986 Repnet® (Option)

Industrial computerised network for management of REP rubber injection press line:

C.I.M. Computer Integrated Manufactory and S.P.C. Statistical Process Control

1988 Curetrac® (Option)

A software package used on a microcomputer for calculating the theoretical cure time of a rubber part and on a REP press for automatically correcting the effective cure time

2002 Isothermould : Thermal distribution of the molds.

Distributed power rods. A 20% reduction of the cure time and a 40% reduction in the dispersion of the molded parts’ properties.

2004

G9 range of rubber injection molding machines

Time saving for change in production and dry cycle times: new records. The G9 range is controlled via a touchscreen with extremely comprehensive features.

V79: a machine with excellent ergonomics: no pit needed for the press, no platform needed for the operator.

Telediagnosis® remote assistance entirely controlled by the customer.

2007

Turbocure®

Up to 50% cure time reduction and higher quality parts. This device consists of two independent modules: TempInverter® and FillBalancer®.

2008

CMS: Compact Multi Station

Unique multistation design for maximum productivy, particularly suitable for rubber metal parts

2013

G10 range: - Intelligent, elegant and efficient

A double wink to its new ergonomic design and its embedded intelligent solutions, the G10 generation is branded "Infinitely Smart".

2014

G9A range - REP's expert know-how on the Asian market

2018

CMX: The CMS in version G10

Multistation machine with latest-generation PLC. Available in two clamping forces (160T or 250T)