Special Presses

Looking for a machine to mold progressive cavity pump stators?

The strength of REP H-Stator machines lies in their ability to adapt to stator molding of all materials, sizes and gauges.

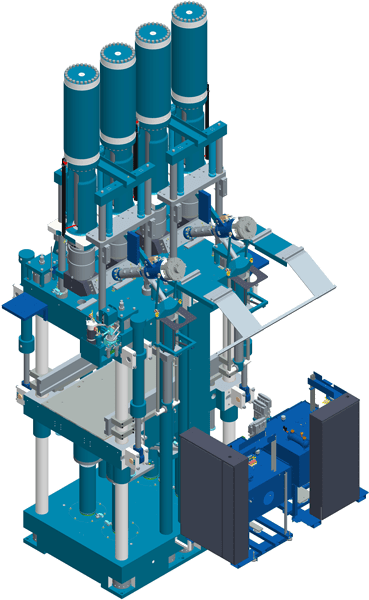

The H00S20 is a flexible press that can produce a wide range of pump stator models, from a few liters to unlimited theoretical capacity, adapting to the different needs of positive-displacement pumps.

H00S20 for molding pump stators

Infinite injection capacity

- Flexible, modular design with dual injection unit integration

- Unlimited injection volume (given by the limitation of the desired volume in the mold)

Modularity and flexibility

-

Stator lengths from 350, 3000 to 5000 mm and more!

-

Multitude of possible diameters from 170 to 350 mm and more!

-

Different materials depending on the application of the finished part: distribution of fluids with viscous, abrasive or sensitive composition (NBR, FKM, HNBR, FFKM, EPDM, VKM, etc.).

Compact design

-

Production footprint of less than 15 m².

Download the flyer:

Horizontal press for fluid handling in a variety of industries

The H-Stator horizontal press is suitable for dispensing and handling various types of fluids found in a wide range of industries, such as :

- the food industry (beverages, paste, compote),

- construction and public works (concrete and other compounds),

- pharmaceuticals / cosmetics / chemicals,

- as well as the gas and oil industries.

Special Presses

Want to mold liquid silicone rubber?

Please note that LSR adaptation is available with all types of REP machines !

Technical features of the V410 LSR

- Clamping force: 1,600 kN

- Dimensions of heater plates: 430 x 510 mm

- Injection capacity: 740 cm3

Special Presses

Are you seeking a solution for dual compound injection?

The dual-compound injection principle can be adapted to all injection presses, regardless of the size of the closing units and of the injection unit.

See for example this V510 which is the ideal solution for the production of thick antivibration parts.

V510 for vibration-control products

- Clamping force 3050 kN

- Dimensions of heater plates: 500 x 630 mm (or 630 x 630 option)

- Injection volume: 2 units of 1000 or 2000 cm3

Special Presses

S0-Series Machines

This kind of machine is especially designed for molding parts such as housing seals

It is available in three different versions :

S03 (300t) , S05 (500t) and S06 (600t)

Version S03 Y10

- Clamping force: 3,200 kN

- Dimensions of heater plates: 1,250 x 630 mm

- Injection capacity: 1000 cc

Version S05 Y10

- Clamping force: 5,000 kN

- Dimensions of heater plates : 1,500 x 630 mm

- Injection capacity: 740 cc

Version S06 Y10 or S06 Y20

- Clamping unit 6,000 kN

- Injection capacity 1,000 cc or 2,000 cc

Special Presses

Do you need a giant molding machine?

The S24 beats all records!

Designed for the manufacture of high-voltage insulators (550 kV), this is one of the largest presses made by REP.

The dimensions of the parts to be injected explain the huge size of the press: 660 mm in diameter, 2,600 mm long, moulded in one go.

The production of a complete insulator takes place, therefore, in between one and four cycles, significantly increasing productivity and the reliability of parts.

The S24 exists in two versions: L50 or L100

S24

- Clamping force: 24,000 kN

- Dimensions of heater plates: 1500 x 3000 mm

- Injection capacity: 25,000 cm3 x 2 (2 injection units)

Special Presses

Duplicate molding of cables under tension in the mold

The S01 has been specially designed for that purpose !

This press is designed for a highly specific use:

Rubber overmolding of cables designed for cutting stones.

The cables must be positioned in the mold in the stretched position, and overmolding takes place successively, “step-by-step”.

A mechanical choice dictated by the application

The “C-Frame” structure, with a 1,000 kN mould clamping force, has been tailored to this press, because this technology offers access to all sides of the mold – something which is essential for successfully undertaking this very special overmolding.

Injection and clamping are, therefore, performed via the top because the platen where the cables to be overmolded are distributed is highly accessible and at a constant level.

This area comprises a system, on either side of the mold, which clamps and stretches four cables simultaneously, thereby positioning them and ensuring the precision of the molded part.

The heating platen fitted in this press also comprises a special temperature regulation mechanism, so that two areas of the mold can be managed at different temperatures.

S01Y10

- Clamping force: 1,000 kN

- Dimensions of heater plates : 1000 x 500 mm

- Injection capacity: 1000 cm3

Special Presses

The dual-compound machine or multiinjection press

Equipping an injection molding machine with a second injection unit has become customary to REP on all types of machines in all configurations:

Special Presses

REP designs your solution

REP provides the answers to problems that conventional techniques cannot satisfactorily resolve.

High level skills backed up by warranties from the REP GROUP!

REP has a team of engineers working on the design and production of molding presses intended for special applications.

We have a solution to each problematic situation!

In the following you can find some examples.

Didn’t found what you are looking for? Get in touch and tell us more about your need!

We can respond to your most complex molding requirements

Take a look at our customized rubber presses:

- Are you seeking a solution for dual compound injection?

We have the solution! - Thick antivibration parts:

Discover the advantages of the V510 dual-compound - Do you need a giant molding machine for the molding of high-voltage insulators?

The S24 beats all records. - Seeking a solution for duplicate molding of cables under tension in the mold?

The S01 has been specially designed for that purpose! - Want to mold liquid silicone rubber?

Take a look at the V410 for LSR injection molding - Want to mold pump stators ?

The H-stator machine is specially designed for that purpose