REP Training Courses

Machines and Workshop

Training courses Operating the machine and Troubleshooting, Workshop Supervision

They are conducted by the Aftersales Department and address to operators, maintenance technicians and adjusters who want to learn how to run, maintain, trouble-shoot a press or supervise the workshop.

Program

Operating a G7/G8 injection press

2023-01-01 - 2032-12-31

Goal of the training:

- To give an overview of the possibilities of the machine

- To enable the trainees to familiarize themselves with the controls and to program and adjust the machine.

Tailor-made and customizable training

Duration : 2 days (14 hours)

Operating a G9/G10 injection press

2023-01-01 - 2032-12-31

Goal of the training:

- To give an overview of the possibilities of the machine

- To enable the trainees to familiarize themselves with the controls and to program and adjust the machine.

Tailor-made and customizable training

Duration: 2 days (14 hours)

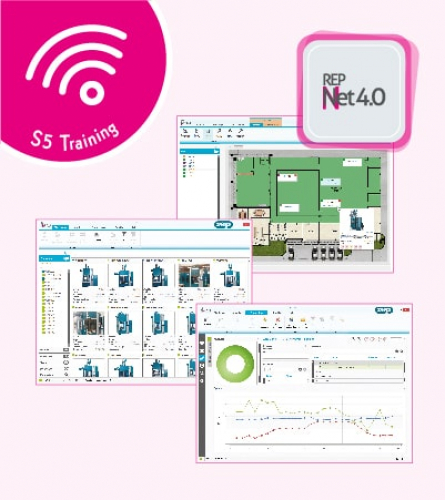

REP Net 4.0

2023-01-01 - 2032-12-31

Goal of the training:

-

Autonomy in the use of the software

-

To know how to make a model of the workshop, an aid to production management

-

To centralize and to transfer molding parameters

-

To ensure cycle traceability (value, measurement, SPC calculation, etc.)

Duration: 2 days (14 hours)

Trouble-shooting and Maintaining G9/G10 Presses

2023-01-01 - 2032-12-31

Goal of the training:

-

To acquire sufficient knowledge of the machine and an efficient methodology for quick troubleshooting

-

To be able to carry out preventive maintenance to ensure optimal operation

Tailor-made and customizable training

Duration: 3 days (21 hours)

Trouble-shooting and Maintaining G7/G8 Presses

2023-01-01 - 2032-12-31

Goal of the training:

-

To acquire sufficient knowledge of the machine and an efficient methodology for quick troubleshooting

-

To be able to carry out preventive maintenance to ensure optimal operation

Tailor-made and customizable training

Duration: 3 days (21 hours)