News Feeds

Congratulations Hervé REVEL!

As of October 1st, the new CEO of REP international is Mr. Hervé REVEL.

With 25 years' seniority, Hervé REVEL has held a number of different positions since joining the R&D Department in 1998.

Well-known to our customers, he was for a time After-Sales Director before becoming Director of the Industrial and Technical Division and finally Chief Operating Officer.

Our shareholders in the ARYES group have chosen to entrust him with the continuation of the REP adventure, which began over 115 years ago!

This change in continuity however opens up new prospects for the future with the development of 3 major projects: CSR, digital transformation and G11

- The 11th generation of rubber injection presses currently under development is due to be unveiled at the K2025 trade show in Düsseldorf.

- At the same time, we are pursuing our digital transformation, the first milestone of which was the switch to a new ERP system in 2021.

- We also intend to implement a sustainable CSR approach in order to contribute to the challenges of sustainable development.

Staying on Course and Rising to the Challenge

The collective adventure can continue!

There is no doubt that the entire management committee, staff and sales and after-sales network will do their utmost to continue the adventure and continue to guarantee the quality of the products and services we deliver to our customers.

Goodbye Mr. Tabar!

After nearly 40 years of service, including almost 30 at the head of the REP Group, our CEO Mr Bruno TABAR retired at the end of September.

An emotional ceremony retraced the milestones of his brilliant career and the major developments in the company under his leadership.

He was made a Chevalier in the Ordre National du Mérite in 2022 for his contribution to France's economic influence abroad through the deployment of our international presence.

The entire REP Group wishes Mr. TABAR an excellent retirement!

Congratulations Hervé REVEL !

His successor is Mr Hervé REVEL, former Chief Operating Officer.

As of October 1, he is the new CEO of the REP group.

Tell us about yourself

- SHS ITALIA is a company specialized in the production of complex technical gaskets and O-Rings in rubber and silicone.

- Our customers operate in various market sectors, the main ones being food and beverages, electrical and electronic components, microtechnologies, gas and sanitary, automotive and e-mobility, measurement technologies.

Focus on the workshop

REP: How many REP presses do you have in your plant? What are the presses in question?

SHS: 4 horizontal injection machines EPG200, 3 horizontal injection machines EPG300 and 1 compression molding machine of 300 tons.

EPG presses are originally developed by RPM s.r.l.,

now a member and subsidiary of the REP group.

REP: Why this choice of models precisely? What advantages and characteristics can we attribute to them?

SHS: If we were to group them into 4 main points, we would say:

1. Dimensions

Dimensions of the machine, with the compact layout of the machine, we save space in the department for a better use of our building surface

3. Remote maintenance

Teleassitance with "Help" software, help us to reduce MTTR time (Mean Time To Repair) in case of faults.

The High Performance Pack enables our production to become autonomous.

2. Energy

Energy saving: we measured a real advantage concerning electrical consumption of our machines that help us to reduce our environment impact

4. Precision

Electric movements: allow us a very precise control of the machine, that means repeatable and stable process. Furthermore, electric movements mean no oil into molding area, it's a big advantage for quality assurance of our product.

We keep under control the consumption of the machine, this allows us to manage the energy price increase without impact on our selling price on the market, it means that we can be competitive.

RPM supported us during the design of our working station and helped us by cooperating with all the other suppliers for cold runner system, temperature control units, heating plates. The result is that we have “built a system” instead of “buy a machine."

REP: What about the ergonomics of the workstation? How can REP machines be differentiated from other models?

SHS: Compact dimensions allowed us to reduce movements of the operators (fewer daily steps), create efficiency in our layout, by a best use of the same space. We reduced the operator’s perceived temperature, by a development of the heating systems of the machine.

Focus on the production

REP: For which use(s) and type of production do you require REP machines?

SHS: We use RPM machines mainly for the production of O-rings and technical articles, even complex ones, but for which automatic operation of the press is possible.

REP: To what extent are these machines a real advantage for you in terms of productivity?

SHS:

- An automatic molding cycle has certain and repeatable time, that means a certain productivity rate

- An automatic cycle means fewer manual operations, that means less variation during the process, in other terms a best controlled process

- Using a reliable automatic machine, means that the operators can focus on added value activities without unexpected operations on the machine

Focus on the finished product

"The versatility, simplicity and wealth of information of REP presses allow us to analyze every aspect in detail to transform ideas into concrete work."

REP & you

REP: How long have you been a REP Customer?

SHS: For 4 years.

REP: What made you come to REP more than to any other company?

SHS: We chose REP because for us it symbolizes:

Availability

Seriousness

Reliability

Future projects

REP: What are your future goals and challenges to complete?

SHS: Our business plan foresees a new step for 6 new machines in the next two years.

SHS Italia recommends REP and RPM services, with a score of:

Welcome to Benjamin PAGANELLI, new Director of our Italian subsidiary

A half-century of existence

50 years ago, REP began building its international network with the creation of a subsidiary in Italy: REP Italiana. This entity is now one of the major pillars of the REP group.

We are proud to celebrate its 50 years of activity and its strong growth!

The subsidiary provides sales and after-sales service in Italy, Greece and Switzerland (italian speaking) in connection with our other subsidiary RPM.

A new management

A new management

To accompany and guide REP Italiana's team, we are pleased to welcome Mr. Benjamin Paganelli.

He holds the position of Director of Operations and Commercial Director since the beginning of 2023.

Let's welcome him onboard! No doubt he will be able to assist and accompany all our customers!

A dynamic staff

In order to ensure a team dynamic and ever-greater responsiveness, Mr. Gianpiero Roscio remains in charge of the subsidiary's After-Sales Service Department.

A growing Italian market

With the arrival of RPM in the group, specialist of the electrical horizontal press, the Italian market represents more than ever an important sector with a strong potential.

![]() You will have the opportunity to meet the subsidiary's team throughout the year and at the future MILAN PLAST fair, which will be held from September 5 to 8, 2023 in Milan, Italy. We will showcase our latest products and solutions on an even bigger stand than in previous editions.

You will have the opportunity to meet the subsidiary's team throughout the year and at the future MILAN PLAST fair, which will be held from September 5 to 8, 2023 in Milan, Italy. We will showcase our latest products and solutions on an even bigger stand than in previous editions.

Meet us and our machines in the RUBBER area dedicated to the entire rubber chain!

Read this post and follow us on LinkedIn!

Positive Outcome of the Trade Show K2022

REP and the organizers are satisfied. The visitors were interested in the diversity of the products and projects of REP!

The largest plastics and rubber industry companies were present in October for the “K Show”, holding once every three years in Düsseldorf.

All in all, 4 machines were showcased at REP’s booth where an international team awaited visitors from all over the world.

It was an opportunity for them to discover and rediscover among others:

- Our exclusive solutions to meet the most demanding needs with the G10 Extended W510 automated press and an example of application in the medical industry.

- Our ability to meet energy saving needs with our new line of compact, electric EPG horizontal presses.

- Our devulcanization technology to recycle production waste.

- The fully electric compression press from Tung Yu.

- Ergonomic peripherals and our new developments with our new silicone stuffer, the HAHN insert feeder and a G10 Core injection press.

- The importance of connectivity for a more competitive industry with our pack of 14 smart modules: REP Pack 4.0.

K2022 in a few figures

More than 176, 000 attendees from 157 different countries and 3037 exhibitors over 175, 000 sqm.

REP on the "K"

- Our booth B57 Hall 14 covers more than 280 sqm!

- 4 machines showcased with 2 of them molding real parts.

- About 40 REP collaborators of 20 nationalities took turns welcoming the visitors on the stand!

- 5 permanently assigned technicians during 3 weeks (before, during and after the show).

- Visitors, collaborators, providers and clients coming from all over the world!

Meet us at the next edition in Düsseldorf from 8 to 15 October 2025!

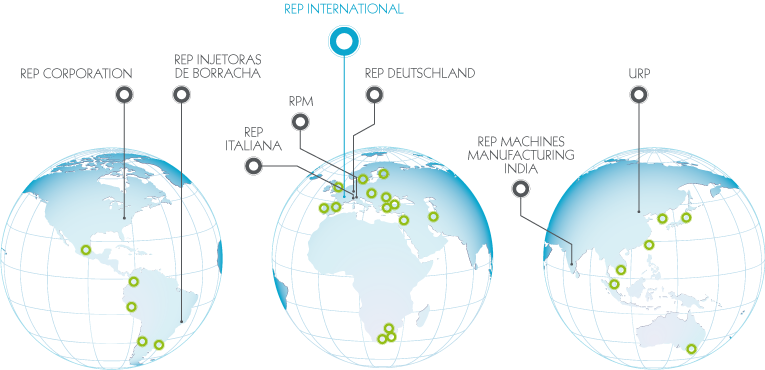

REP Group now counts eight subsidiaries!

Acquisition of a Company recognized for its Know-How

Who?

The company RPM Srl., located in Paderno Franciacorta, in the Italian province of Brescia, and specialized in horizontal presses

When?

Starting from May 1st, 2022

How ?

The founding directors of RPM, Gianfranco and Marco Inverardi, will remain shareholders and at the head of RPM.

The center of competency for the horizontal machines business will remain in Italy.

Mr Bruno TABAR surrounded by the founding directors of RPM, Gianfranco and Marco INVERARDI

Extension of our Machine Range

The integration of RPM into the REP group adds an innovating range of horizontal hydroelectric machines.

These particularly compact machines have already proven their value on the highly competitive Italian market.

Thanks to RPM, we consolidate our market position in the field of horizontal machines.

The range now consists of:

- rubber compression molding presses

- composite molding presses

- vertical injection molding presses and horizontal injection molding machines for rubber, liquid silicone and TPV

- machines for the devulcanization of rubber waste.

Expansion of REP's Network

RPM joins our network of 8 subsidiaries and about thirty sales and aftersales agents.

REP thus holds its solid presence throughout the world.

Having local experts all around the world means:

- greater responsiveness

- simplified exchanges

- quality support

- on-site service

Getting to the contact data of RPM

New Team at the Head of the Market Development Division

With the mission to pool the group's know-how for improved customer satisfaction

Thorsten JUST, Managing Director of our subsidiary REP Deutschland since 2018, takes over the management of the Market Development Division, including all sales and marketing actions worldwide.

He succeeds Mr. Stéphane Demin and becomes the Global Sales and Marketing Director of the REP Group.

A few words from Thorsten JUST :

"I am very proud to take over more responsibility within the REP Group, known as one of the leading manufacturers of rubber injection machines, and to drive an experienced team who is focused on and dedicated to customer satisfaction!”

To support Mr. Thorsten Just in the Sales Management, we are pleased to announce the arrival of Mr. Gérald Serero as Deputy Sales Director.

He is also the Export Area Manager for the sales area of the Iberian Peninsula.

A few words from Gérald SERERO :

"Happy to join a team of experts in elastomer injection molding, focused on bringing REP know-how to support customers with their molding application challenges."

We wish both of them success and fulfillment in their new positions!

You will have the opportunity to meet our entire team very soon on fairs and shows or online while attending one of our webinars!

Bruno Tabar, C.E.O. of REP international has been awarded the prestigious rank of Knight in the National Order of Merit.

REP is honored by the distinction granted to its President, Bruno TABAR, who was elevated to the rank of Knight in the National Order of Merit on the proposal of Mr. Bruno LEMAIRE, Minister of the Economy, Finance and Recovery.

Rewarding international economic influence

This distinction has been awarded in recognition of the contribution to France's economic influence abroad for more than 30 years, highlighted by the deployment of our international presence.

French historical know-how as an injection molding machine manufacturer

As a pioneer of innovation in this field in the 1960s, REP has greatly contributed to the development of the elastomer industry and continues to do so.

Thanks to the strength of its global network of subsidiaries and agents, who provides local sales and technical support, REP has supported the industrial development of rubber parts throughout the world.

With more than 12,000 machines installed in 77 countries, everyone who wants to mold elastomer parts based on injection molding can have access to the technology of REP.

This medal to our CEO translates pride and great recognition!

A few words from Mr Bruno Tabar

"This national recognition acknowledges the remarkable way REP has evolved and it rewards and honors all those who contributed to its development on the global market.It encourages further efforts to address the challenges that the new generations are already facing and also provides a touch of sparkle to brighten our sometimes weary daily lives. It further sharpens our ambition to rank among the best and it calls for continuous projects in line with our vision and path for the future."

A reputation worthy of the award

Let's imagine ...

Let's imagine ...

- an American company who wants to produce gas masks

- or an Indonesian company who wants to inject silent blocks

- or even a factory belonging to a large automotive group producing vibration mounts

- a company from the Maghreb wanting to manufacture washing machine door seals

- a rubber seal factory in Romania

- a Spanish component supplier looking for automation solutions

- in Australia, Ethiopia, Sweden, Russia, China, Canada, Germany, India, Mexico etc.

... everyone, everywhere in the world, may benefit from REP's services!

A blue starred ribbon

Blue as the color so typical of REP!

Did you know? The National Order of Merit is:

- the second national Order, designed to honor French citizens in complementarity with the Legion of Honor,

- a reward for outstanding merit acquired in the service of the nation in a civilian or military, public or private capacity,

- a highlight of a French activity participating in national success,

- an encouragement for the country's driving forces.